עיוות החוט הוא קל וחשוב כשמדובר בחוטים. כלומר, זה התכנסות של חוט וקצה על מחבר, ודחיסתם אחד בתוך השני כדי שהחשמל יוכל לעבור עם קושי מינימלי. כאשר מתבצע כראוי, עיוות מבטיח חיבורים יציבים ובטוחים. אך אם מתרחשת טעות, החוטים עלולים לה aflox או ליצור ניצוצות רעים העלולים להרוס מכונות ואפילו לגרום לשריפות. עיוות טוב חשוב באותה מידה כאן ב-KEFA. לכן אנו רוצים להציע טיפים שיעזרו לכם למנוע כמה צרות נפוצות. למידת הדרך הנכונה ל מחברות דחיסה חוסך זמן וכסף וחשוב ביותר להבטיח שהמכשיר שלך לא ייכשל מוקדם בגלל חיבור מכני לא מספיק. בואו נהיה ברורים לגבי מה בדרך כלל משתבש ואיפה אתה יכול ללמוד את הדרכים הטובות ביותר לעשות את העבודה הזאת.

מהן הטעויות הנפוצות של חיתוך חוטים להימנע לפי קונים בגדול?

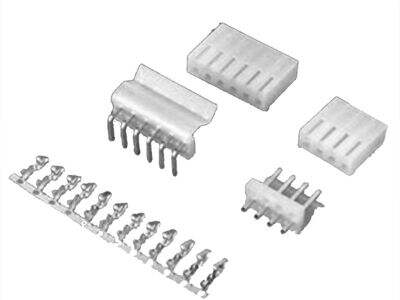

זה גם קל לעשות טעויות תחת רכישת מחבר crimp בכמויות שיכולות לגרום לבעיות במורד הדרך. אחת הטעויות הגדולות ביותר היא להשתמש בקישור שגוי לגודל של החוט. אם המחבר גדול מדי, הוא לא יחזיק את החוט בצורה בטוחה. מעט מדי, והסוללה ניזוקת בקלות בעת crimping; יותר מדי, וזה לא יכול להישאר במקום. לדוגמה, אם חוט כבד נדבק במתחם קטן, חוטים של החוט עלולים להישבר ולהשאיר חיבור גרוע. טעות נוספת היא לא לפשוט את החוט נכון לפני הגירוד. חלק מהקונים האלה השאירו בידוד עבה מדי על החוט, כך שהחלק המתכתי לא עושה מגע טוב עם המחבר. או שהם מעל גז, שבו אין שום בידוד נשאר כך החוט יכול קצר נגד משהו אחר. בנוסף, שימוש בקישורים זולים או מחברי חוטים עלול להרוס את העבודה. מחברים זולים עשויים להיות ממתכת דקה ושבירה שמתעortion או נשברת בקלות. כלים שלא מבצעים עבודה טובה של הפעלת לחץ עלולים לרסק את החוט או להשאיר אותו רופף. אנשים לפעמים שוכחים לבדוק את החיבור לאחר ביצועו. חיבורים לא נכונים נשארים מוסתרים עד שמישהו מבצע מבחן משיכה פשוט או משתמש במונה, עד שהם מתחילים להיכשל בשטח. ב-KEFA, אנו ממליצים שכל קונה סיטונאי יבדוק כל אצווה שנרכשה. בעיה נוספת שאנשים נתקלים בה היא ערבוב של מחברים וחוטים, מבלי לדעת מה תואם למה. למשל, חוט אלומיניום ומחברים מנחושת דורשים טיפול מיוחד או שהחיבור עלול להתחמצן במהירות. זה עלול להוביל לصيانות יקרות וללקוחות לא מרוצים בהמשך הדרך. על ידי רכישה מספק מכובד כמו KEFA, תקבלו את החלקים הנכונים וכמה עצות כדי להימנע מהטעויות האלה. אנו מבטיחים שכל מוצר עובר בדיקות איכות קפדניות. לקוחות סיטונאים ירצו גם לאמן את עובדי המכירות שלהם על חיבור חוטים. זה מפחית טעויות ומשפר את הבטיחות. למידה והתנסות בחיבור חוטים יכולים לחסוך מצרים בהמשך.

איפה לקבל טכניקות חיבורות כפייה ברמה טובה על אספקה חשמלית בקופות?

מציאת השיטה האידיאלית לגימור אינה תמיד פשוטה, אך היא קריטית לקונים בجمل שמבקשים להשיג תוצאות טובות. KEFA כלל מדריכים וקישורים שימושיים בנוגע לאיך לגומרים חוטים בצורה נכונה. הם נעים מהגודל המתאים של המחבר, דרך הכלים הדרושים. תראו הוראות צעד אחר צעד וסרטונים שצולמו על ידי אנשי מקצוע בעלי מחויבות לאמינות ולבטיחות. לעיתים קרובות, קונים משתמשים בהשערות או באינטואיציה ישנה בעת רכישות, אך לעתים קרובות נגרמות טעויות. חומרי הלימוד של KEFA מדגימים למה כל שלב חשוב וכיצד להימנע מטעויות נפוצות. מקום טוב נוסף ללמוד ממנו הוא הסדנאות וההדרכות שKEFA מספק. הסרטונים מאפשרים לקונים לתרגל גימור בהדרכת מומחים. החווייה המעשית עוזרת להם להרגיש איך נראה גימור טוב, כמה לחץ נדרש, ולהכיר מצב בו הגימור אינו תקין. שאלות יכולות לקבל מענה מיידי, וזה עדיף על פני קריאה בלבד של הוראות. יתר על כן, ישנו תמיכה טכנולוגית ללקוחות. אם אינכם בטוחים איזה מחבר או כלי מתאים לחוט שלכם, פנו אלינו. אנו נענים במהירות ונותנים ייעוץ כנה וברור, שנבנה מניסיון מציאותי. חלק מהקונים מנסים לחפש באינטרנט או לצפות בסרטונים אקראיים, אך לא כל המקורות אמינים או נכונים. הגישה של KEFA פותחה לאורך שנים רבות בשכנות לתעשיות שבהן חיבורים חשמליים עמידים הם חיוניים. כלומר, מה שאנחנו משתפים איתכם עבר מבחנים ונבדק. אם אתם קונים בכמויות גדולות, לדעת שהעובדים שלכם מבינים את זה מפחית בזבוז, חוסך כסף ושומר על התקדמות הפרויקטים בזמן. כשכולם יודעים כיצד לגמור, נוצרת ביטחון, ומשמעות הדבר היא ש-KEFA הוא שותף, לא ספק. גימור חוטים אינו קל כמו שזה נראה, ודורש מיומנות וכלי עבודה איכותיים. KEFA עוזר לכם להישאר מוכנים כדי לוודא שאתם עושים זאת נכון בכל פעם.

בעיות נפוצות בשילוב תיילים וכיצד להימנע מהן עם כמות גדולה מכונה לייצור קבלים

אם עובדים עם שילוב תיילים, במיוחד בעת ייצור קבלי כבלים למכירה בجملة, יש לדעת לזהות ולתקן בעיות בצורה נכונה. כשאתם עושים שילוב, אתם למעשה דוחסים את התייל ו מחבר קריש יחד בכוח מופרז. אם זה לא נעשה נכון, החיבור יכול להיות רופף או לא בטוח. כאן ב-KEFA, אנו רוצים לוודא שאתם יודעים איך להימנע מהטעויות האלה ושיהיו לכם הכבלים במצב אופטימלי בכל פעם שאתם צריכים אותם.

אחת הבעיות הללו היא חיבור רופף. זה קורה אם החוט לא מוכנס עמוק מספיק לתוך בית המחבר. אסור שתהיה התפתלות או משיכה של החוט; משחק כזה פירושו לחיצה רופפת. כדי למנוע זאת, ודאו שאתם משתמשים בכלי הלחיצה הנכון ולחצו עליו עד שתשמעו צליל קליק או תחושו התנגדות. בנוסף, ודאו שהחוט מפשיר באורך הנכון לפני הלחיצה. יותר מדי חוט חשוף חשוף עלול לא להישאר במקומו; מעט מדי, והחיבור עלול להיות חלש.

בעיה נוספת היא חוט מחוסם. קיים סיכון לשבירת חוטי המתכת בתוך המחבר אם לוחצים חזק מדי בעזרת כלי הלחציה. זה יוצר חיבור חלש שעלול לגרום לחוט להישבר בשלב מסוים. כדי להימנע מזה, יש להשתמש בכלים שתוכננו במיוחד לגודל החוט והמחבר בהם משתמשים. כלים להלחצה של KEFA מספקים את הלחץ המושלם כך שהחוטים שלכם יהיו בטוחים וחסונים.

לפעמים אנשים ישתמשו בגודל לא נכון של מחבר עבור החוט. אם ניתן למשוך את המחבר, הוא גדול מדי או 느슨 מדי. יש לבדוק את הגודל המודפס על החוט ועל המחבר לפני תחילת העבודה. הסר את הספקולציות בבחירת החלקים הנכונים וקבל את כל מה שצריך כדי להשלים את ה-KEFA של ילדך בהזמנה פשוטה אחת.

איך קונים סיטונאים יכולים לדעת על התאמת ואיכות של מחברי קרימפ?

אם אתם קונים כמויות גדולות של מחברי קרימפ לעסק שלכם, חשוב שתוכלו לזהות את הטובים שביניהם. קניית מחברים לא נכונים עלולה להוביל לבעיות כמו חיבורים לקויים, בעיות חשמליות והפסד כספי. ב-KEFA, אנחנו רוצים לעזור לקונים סיטונאים להבין על מה כדאי להקפיד בעת בחירת מגעי הקרימפ.

הדבר הראשון שצריך לעשות הוא לבדוק שהקונקטור יכול להכיל את גודל החוט שמתכננים להשתמש בו. למחטים יש עוביים שונים, או מדידות. מה שעושה קונקטור טוב למשבצת עבה אינו בהכרח טוב למשבצת דקה, וההפך. בחירה לא נכונה של הגודל עלולה לגרום לחיבורים רופפים או נפגמים. ברשימות המוצרים של KEFA יופיעו בפניך, במונחים ברורים, איזה גדלי חוט מתאימים לכל קונקטור כדי שתוכל לבחור את הנכון.

שלב הבא – שקול את איכות החומר. קונקטורים איכותיים מיוצרים מחומרים שמגלים ביצועים טובים בעת העברת חשמל ועמידים בפני חלודה או קורוזיה. הקונקטורים הזולים עשויים להיראות בסדר, אך מיוצרים ממתכות גרועות שימססו בקלות. קונקטורי הצמצום של KEFA מיוצרים מסגסוגת נחושת מובחרת, שנחשבת לבלתי נמוכת חלודה לאחר ציפוי. זה מבטיח שהכבלים שלך יישארו יציבים ויסוגלו לשימוש לאורך זמן.

צורת המחבר היא תכונה נוספת שחשוב לקחת בחשבון. למחברים מסוימים יכולה להיות צורה ייחודית, או לכלול תכונות נוספות שמשפרות את ביצועי הלحام. למשל, המחבר עשוי לכלול עצור למניעת הכנסה מופרזת של החוט. KEFA פיתחה את המconnectors האיכותיים ביותר المتوافق עם כלי הקרימפ שלנו, כך שלא תצטרכו להתמודד עם חיבורים חלשים או נזק לחוט.

איפה ניתן להשיג מחברים עמידים מסוג Crimp לcrimping של כמות גדולה של חוט?

אם אתם עובדים על פרוייקטים גדולים הדורשים כמות גדולה של מחברי crimp, חשוב שתמצאו את המקום הטוב ביותר לקנייתם. מה שאתם רוצים הם מחברים שיישארו לאורך זמן, יעבדו היטב ולא יגרמו לבלבול. KEFA מכירה את הדרישה הזו ויכולה לספק לכם מחبري crimp אמינים עבור משימות crimping של חוט עבה.

הדרך הטובה ביותר להשיג מחברים באיכות גבוהה היא דרך מקור מהימן העוסק במוצרים ללחיצה. KEFA מספקת מגוון של מחברים עמידים שמיוצרים מחומרים עמידים. כלומר, המחברים לא יישברו או ייכשלו גם לאחר שימוש מרובה. מחברים לחיי נצח חוסכים בתקציב שלכם כיוון שאין צורך להחליף אותם לעיתים קרובות.

גורם חשוב נוסף הוא זמינות. כשאתם עובדים על פרוייקטים גדולים, תצטרכו את הממחברים הרבה וגם בכמויות גדולות. ב-KEFA יש אוסף עצום של כל סוגי המחברים הלוחצים ובגדלים שונים, כך שתוכלו בקלות למצוא את מה שאתם צריכים תוך דקה. זה יעזור לכם להישאר בלוח הזמנים של הפרוייקטים שלכם.

חפשו ספקים שמספקים לכם מחברים המתאימים לכלי הלחיצה שלכם. KEFA מפתחת מחברים התואמים למכונות הלחיצה ולכלי העבודה הידניים שלנו. זה מונע שגיאות ומעלה את היעילות, במיוחד כשנעזרים בהלחמת מאות או אלפי חוטים.

תוכן העניינים

- מהן הטעויות הנפוצות של חיתוך חוטים להימנע לפי קונים בגדול?

- איפה לקבל טכניקות חיבורות כפייה ברמה טובה על אספקה חשמלית בקופות?

- בעיות נפוצות בשילוב תיילים וכיצד להימנע מהן עם כמות גדולה מכונה לייצור קבלים

- איך קונים סיטונאים יכולים לדעת על התאמת ואיכות של מחברי קרימפ?

- איפה ניתן להשיג מחברים עמידים מסוג Crimp לcrimping של כמות גדולה של חוט?