Cable terminal blocks are extremely significant for keeping your wires clean and organized. If you need to connect a lot of wires together, a cable terminal block can help you achieve that quickly and safely. It’s kind of like a little box that keeps all your wires from tangling up. May be just an intelligent connector that helps you, join the wires in a small way. Think of KEFA din rail power distribution terminal blocks as a junction point where all those wires meet in order to form a stronger connection. If you do not have a cable terminal block, the wires may be messy, and it may not be easy to determine where each wire goes.

Once you know how, KEFA din rail power distribution terminal blocks is easy to install a cable terminal block. Start by rounding the wires you need and ensure they are of correct length. Next, remove the insulation at each end to expose the metal. After that, insert the wires into the terminal block and tighten the screws to secure them. After all the wires are placed in the terminal block, you can connect the block to the relevant device or the machine you are working with.

A terminal block cable terminal offer various advantages. The biggest advantage is that KEFA din rail power distribution terminal blocks always keeps your wires organized and prevents it from getting tangled. It also makes it easy to swap out or repair your wires since you only have to remove one wire from the terminal block without disturbing the rest of the wires. In addition, cable terminal bricks represent solid connections between your wires, which is an important feature for ensuring everything works fine.

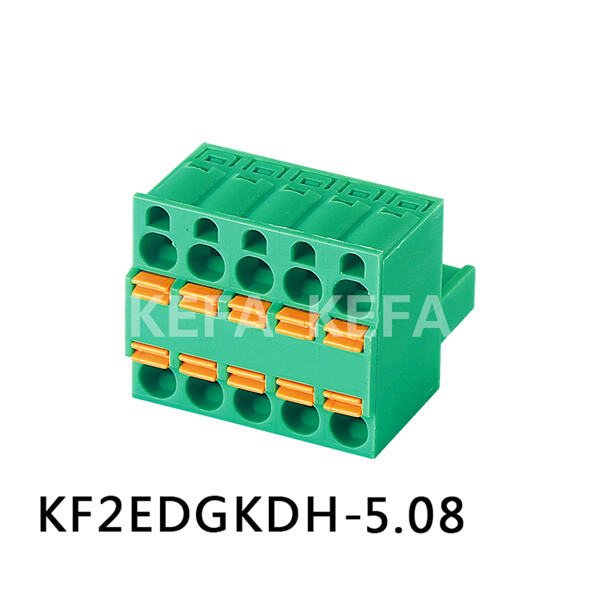

Consider how many wires you plan to connect when selecting KEFA power distribution terminal block for your project; ensure that the terminal block provisions enough slots for all of your wires. It is also a good coaching to consider the size of the wires you are using and check if the terminal block can port them. Now think about where the terminal block is going to be, whether it needs waterproofing or heat resistance.

Here are some troubleshooting steps you can take if you have issues with KEFA power distribution terminal block. Begin with checking all your connections to ensure that everything is tight and secure. If that doesn’t do the trick, you could swap out the terminal block for a new one to see if that takes care of the issue. It is also a good idea to label your wires before they are threaded through the terminal block so you’ll know what you are connecting later on.

With a technical team of over 50 highly skilled professionals, the company has over 30 years of deep expertise in the terminal block industry. This dedicated team drives innovation, developing and launching more than 30 new products annually to meet the evolving demands of the market. Their extensive experience, combined with a focus on precision and advanced technology, ensures the delivery of reliable, high-quality solutions. By consistently pushing the boundaries of design and functionality, the team solidifies the company's position as a trusted leader in providing smarter, safer, and more efficient electrical connection solutions.

Our company is supported by a dedicated 30-person sales team, ensuring personalized and efficient service for every client. With a 24-hour customer service hotline, we are always available to address inquiries, provide technical support, and resolve any issues promptly. Additionally, we offer multiple online sales platforms, making it convenient for customers to browse products, place orders, and access support anytime, anywhere. This comprehensive approach ensures a seamless and reliable experience for our clients, backed by expertise and accessibility at every step.

Established in 1990, CIXI KEFA ELECTRONICS CO., LTD is a leading enterprise specializing in the research and development, production, and after-sales service of terminal blocks. With over 30 years of dedicated focus on the terminal block industry, the company has built its reputation on core technology, a strong corporate culture, and strategic vision. Offering ten product series with over 10,000 styles, CIXI KEFA serves customers across diverse industries, including industrial automation, rail systems, security and protection, lighting, and elevator systems. Our decades of expertise and innovation have solidified our position as a trusted leader in the terminal block sector.

KEFA operates from a 25,000-square-meter factory with a 40,000-square-meter building area, adhering to strict production standards and maintaining clean, modern workshops. Certified with ISO9001 and ISO14001 management systems, the company ensures high-quality production and environmental responsibility. With a professional R&D team and skilled technical personnel, KEFA established its own witness laboratory in 2006, equipped with advanced testing equipment such as film thickness measurement machines, needle flame testers, stiffness testers, and temperature rising machines, ensuring product reliability and innovation. Rooted in robust manufacturing fundamentals and embracing Industry 4.0, KEFA is committed to becoming a leader in terminal blocks, delivering simpler, safer, and more intelligent electrical connection solutions.